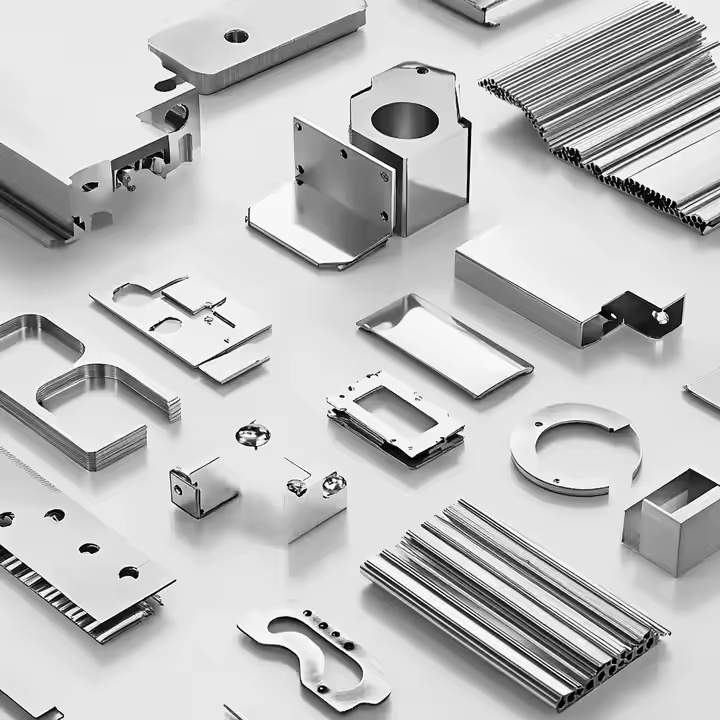

Metal stamping, an ancient yet modern manufacturing process, has played a pivotal role in the industrial sector since its inception. It utilizes molds and stamping equipment to apply pressure to metal sheets, causing plastic deformation or separation to produce parts with specific shapes, sizes, and properties. This article will take you into the world of metal stamping, exploring its basic principles, types, applications, and future developments.

Basic Principles of Metal Stamping

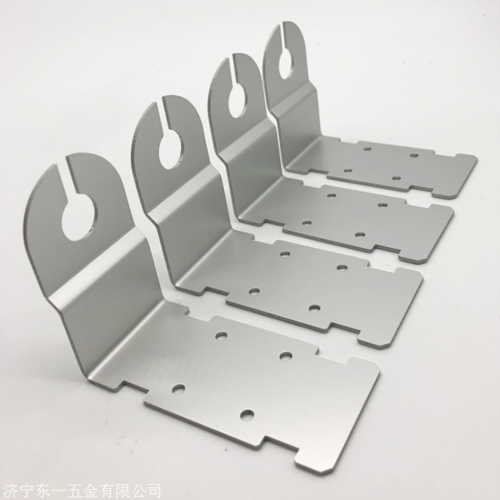

The basic principles of metal stamping are not complex. It uses a stamping press or power press, where a punch moves up and down to deform metal sheets or tubes on a mold. The mold constrains the material’s shape and size to create the desired components with the required specifications. This process is efficient and precise, making it ideal for mass production.

Types of Metal Stamping

Metal stamping processes are diverse and can be categorized in various ways. Common types include bending, blanking, embossing, debossing, flanging, forming, deep drawing, and punching. These processes each have unique applications in manufacturing, fulfilling the diverse needs of component fabrication.

Applications of Metal Stamping

The scope of metal stamping applications is vast, covering almost every industry that requires metal components. From automotive manufacturing to home appliances, aerospace to healthcare, military defense to electronics communication, metal stamping plays an irreplaceable role. For instance, in the automotive industry, metal stamped parts are key components in body manufacturing, such as engine hoods, side panels, and trunk lids. In aerospace, metal stamped parts are used to create structural components for airplanes and engine parts.

Advantages and Challenges of Metal Stamping

Metal stamping offers many advantages. First, it allows for the efficient and precise production of large volumes of uniform parts while maintaining low costs. Second, metal stamped parts have high accuracy and repeatability, meeting stringent tolerance requirements. Additionally, the mold costs for metal stamping are relatively low and easy to replace and maintain.

However, metal stamping also faces some challenges. For example, the mold manufacturing requirements are high, and the process is primarily suited for large-scale production. Moreover, scrap material and edge waste may be produced during the metal stamping process, requiring proper management to minimize resource waste.

The Future Development of Metal Stamping

With technological advancements and industrial progress, the metal stamping process continues to innovate and improve. In the future, metal stamping will focus more on the recycling of materials and energy conservation, driving sustainable development. At the same time, with the widespread use of automation and intelligent technology, the production efficiency and product quality of metal stamping will be further enhanced.

Conclusion

As an essential manufacturing process, metal stamping plays a crucial role in the industrial sector. With its efficiency, precision, and cost-effectiveness, it meets the mass demands for metal parts in manufacturing. With technological progress and industrial development, the metal stamping process will continue to evolve, contributing more to the growth of the industrial field. Let us look forward to the exciting future of metal stamping!